-

Inquiry - 1,1-Bis(tert-amylperoxy)cyclohexane (TACH)

CAS 15667-10-4

- Molecular Formula: C₁₆H₃₂O₄

- Molecular Weight: 288

- UN No.: 3103

-

- Widely used as a polymerization initiator for bulk styrene polymerization at temperatures ranging from 90°C to 120°C. It also acts as an initiator for copolymerization processes involving styrene, acrylonitrile, acrylates, and methacrylates.

- TACH is a highly efficient curing agent for unsaturated polyesters (UP resins), making it ideal for pultrusion, SMC, DMC, and BMC molding processes. Its excellent catalytic performance in SMC and BMC processes ensures superior results.

-

Inquiry - 1,1-Bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane (CH335)

CAS 6731-36-8

- Molecular Formula: C₁₇H₃₄O₄

- Molecular Weight: 302

- UN No.: 3101, 3103, 3107

-

- It is also used as a cross-linking agent for natural rubber, silicone rubber, diene rubbers, polyurethane, and EVA copolymers. Compared to other peroxides, CH335 operates at lower cross-linking temperatures and produces less odor, making it the preferred choice for black resin products in BMC/SMC curing applications.

-

Inquiry - 1,1-Bis(tert-butylperoxy)cyclohexane (CH)

CAS No.: 3006-86-8

- Molecular Formula: C₁₄H₂₈O₄

- Molecular Weight: 260

- UN No.: 3105

-

- CH is used in styrene polymerization processes, operating best at temperatures between 90°C and 120°C. It also acts as a reliable initiator for copolymers like acrylonitrile, acrylates, and methacrylates.

- This organic peroxide is highly effective as a curing agent for unsaturated polyester resins (UP resins) in high-temperature applications. It’s a go-to option for curing in processes like SMC, DMC, and BMC, with optimal temperatures ranging from 120°C to 170°C.

-

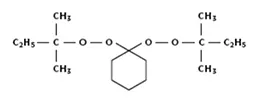

Inquiry - 2,2-Di(tert-butylperoxy)butane (DBPB)

CAS 2167-23-9

- Molecular Formula: C₁₂H₂₆O₄

- Molecular Weight: 234.3

- UN No.: 3103

-

- DBPB is primarily used in the polymerization of styrene and styrene copolymers via suspension methods, within a temperature range of 90°C to 130°C. It can be blended with isododecane, ethylbenzene, or mineral oil, depending on specific customer requirements.

- Compared to thermal polymerization, DBPB offers several advantages, including lower residual monomer levels, higher conversion rates, and faster reaction speeds.

Chemical Auxiliary Agents